The Rapidox 1100 range is one of the company’s most popular, cost-effective and versatile oxygen gas analysers. A single gas analyser designed for analysing low ppm levels or 100% oxygen with either zirconia or electrochemical sensors.

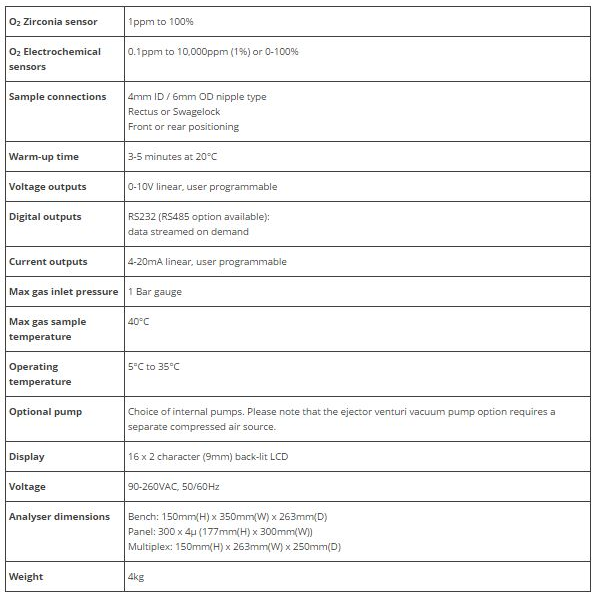

Users have a choice of two electrochemical oxygen sensors, one for low ppm measurements of 1ppm to 1% and another for 1–100% oxygen range. Electrochemical sensors are ideal for applications where VOC’s or flammable gases are present in the gas sample.

Analysers fitted with the zirconia oxygen sensor provide fast and accurate gas analysis over the range 1ppm to 100% O2. Continuous on-line oxygen gas analysis is available, with a typical response time of approximately 5 seconds.

An internal pressure sensor compensates for small changes in gas pressure to ensure that the readings remain stable. A powerful long-life pump draws in a gas sample at a flow rate set by the user between 0-1 litres per minute. Alternatively, the pump can be independently switched off and the unit operated under flowing gas conditions.

Other variations of the model include a three-channel multiplex version, which allows for three gas streams to be sampled from separate points. Gases can be analysed in sequence or at intervals set from the controls (front keypad or software). The Rapidox 1100 oxygen gas analyser can also be used to control an external proportional flow control valve (PFC). This is particularly useful within inert gas blanketing applications, where the analyser can regulate the level of gas based on the measurement of oxygen via the PFC control function.

Standard features on all models include two fully programmable alarm circuits (volt free contacts), programmable analogue outputs (0-10V and 4-20mA), easy calibration (user selectable gases), RS232 / RS485 communications and complete data-logging software.

Available with gas fittings located on the front or rear of the analyser, as a bench mount or with a bezel front panel to incorporate the instrument within an industry standard test equipment rack. The multiplex version is available with rear gas fittings only.

Cambridge Sensotec offers a range of Rapidox servicing options. Regular gas analyser calibration significantly increases the measurement, reliability and repeatability of equipment. A full service is available via state-of-the-art automated stations, designed to calibrate Rapidox gas analysers accurately and efficiently.

Fast and accurate gas measurement response times

Easy user calibration procedure (with appropriate calibration gas)

Low maintenance and long sensor life expectancy

Variable speed pump fitted for sampling the gas

Large back-lit LCD

Two fully programmable alarm settings: high and low, open or closed relays

0-10V and 4-20mA analogue communications (both fully programmable)

Digital RS232 output (RS485 available upon request)

Software package includes full control of the analyser, live graphing and MS Excel compatible data-logging

PIN code protection

Operates on any worldwide mains voltage (90-260VAC)

Suited for a wide range of industrial and research-based applications

(028) 22 611 711

(028) 22 611 711

Danh mục

Danh mục

High Purity Northwest Inc.

High Purity Northwest Inc.

Phóng Điện Cục Bộ

Phóng Điện Cục Bộ

Gọi điện

Gọi điện SMS

SMS Chỉ Đường

Chỉ Đường